So here it goes, my project thread (2nd gen)

#891

I dont have an answer for that. It may have to do with it being a VR sensor. I too have a hard time with it not working slow. Who knows though. It may work fine. I basically posted the picks i posted here and asked if anyone had any objections to it. The only thing said was to check the voltage at cranking to see if it will work. Not that it wont, sorry if I was unclear on that. The Vortec is a Hall Effect and I think they were wanting me to use a Hall Effect for what ever reason. No mention of why. DIY sells a generic Honeywell sensor for $40, I can get the Vortec dizzy for 50 shipped and it has the wheel and sensor mounted nicely. Thats the reason I want one.

#892

Well this place has died. The new format is really killing the second gen section.

In order to keep the place alive I will submit. I recently purchased a complete set of Equiss gauges for the car. I also have a aluminum dash panel on the way with holes custom cut to my wants. I also have a new in tank fuel set up from Tanks Inc so I can convert the stock tank to EFI. Hmm what else. I got a new balancer and am considering a DSE mini tub.

I'll post picks of the dash when it gets here. The tank I will do a write up on so others can see how I did it. Until then HELLLOOOOOoooOOOOOooooOOOOoooo

In order to keep the place alive I will submit. I recently purchased a complete set of Equiss gauges for the car. I also have a aluminum dash panel on the way with holes custom cut to my wants. I also have a new in tank fuel set up from Tanks Inc so I can convert the stock tank to EFI. Hmm what else. I got a new balancer and am considering a DSE mini tub.

I'll post picks of the dash when it gets here. The tank I will do a write up on so others can see how I did it. Until then HELLLOOOOOoooOOOOOooooOOOOoooo

#893

Well this place has died. The new format is really killing the second gen section.

In order to keep the place alive I will submit. I recently purchased a complete set of Equiss gauges for the car. I also have a aluminum dash panel on the way with holes custom cut to my wants. I also have a new in tank fuel set up from Tanks Inc so I can convert the stock tank to EFI. Hmm what else. I got a new balancer and am considering a DSE mini tub.

I'll post picks of the dash when it gets here. The tank I will do a write up on so others can see how I did it. Until then HELLLOOOOOoooOOOOOooooOOOOoooo

In order to keep the place alive I will submit. I recently purchased a complete set of Equiss gauges for the car. I also have a aluminum dash panel on the way with holes custom cut to my wants. I also have a new in tank fuel set up from Tanks Inc so I can convert the stock tank to EFI. Hmm what else. I got a new balancer and am considering a DSE mini tub.

I'll post picks of the dash when it gets here. The tank I will do a write up on so others can see how I did it. Until then HELLLOOOOOoooOOOOOooooOOOOoooo

I've been deep into a major home renovation, and don't even have time to turn a wrench on my BBC powered Falcon gasser project yet!

I've been deep into a major home renovation, and don't even have time to turn a wrench on my BBC powered Falcon gasser project yet!I've used Equus gauges on a couple projects and found them to be a great gauge at a very reasonable price tag!

#894

I was wondering that too, the "new format" is a year old already. And with all the subsections out in the great wide open, I don't understand what the lack of exposure issue could be? Or perhaps he's reefering to something changing with the mobile site?

#897

Well finally got some work done. I got a kit from Tanks Inc instead of shelling out a grand to Ricks for a stainless one.

I got this pick up with a Walbro 255 for $235. They have a 400 lph pump for $295.

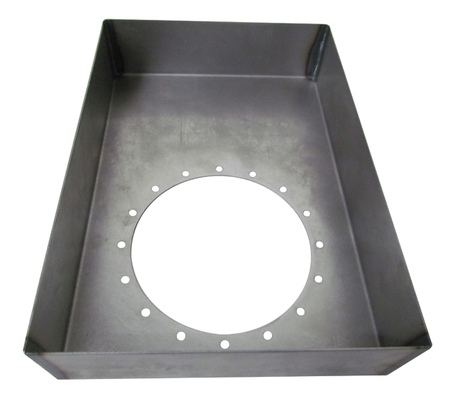

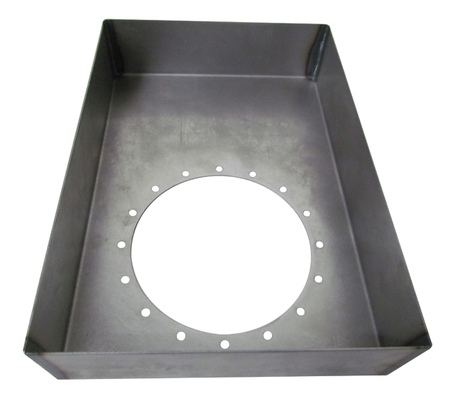

Then grabbed this nice littler recessed pocket that is laser cut to fit the pump.

I got the roll over vent because its cheap and i needed one. Why not get one that fits the left over hole in the pickup?

I took the sending unit out of my stock tank a year ago and let the fumes vent as the may. The tank was mostly empty so I dumped it and filled it will a degreaser and water. Then I said a small prayer and began to cut.

Gravy

After this I dumped the water and wiped out real good. Here is where my problems started. I had bent up some sheet metal that was like expaned steel but with .080" holes. Nice for a baffle I thought. During welding I left my helmet in the car so I tried to weld by brale. No luck! Using the gun to hide the light caused me to burn right through the tank. Dumb SOB! I hate myself sometimes. I was reminiscing during the hole cutting. There a small dent in the tank from the day I got the car 15+ years ago and I was thinking I wouldnt fix it and leave it as a reminder of the day I got my car and towed it over a cylinder block. But it wasnt to be. So I got a new one from Rock Auto for about $100 shipped to my door in three days. Good times!

Where was I? Oh yeah! Making holes! This time I went straight for the plasma cutter and had it over in seconds. I cant beleive I forgot to snap pics of the welds but it was bad. It was brutal. I got lazt and didnt dress the inside of the tank. I wish I had. The galvanizing on the inside of tha tank screwed my welds up so bad I am embarrassed of them. I luckily had two sticks of brazing rod and went over the MIG welds with braze to make sure it was sealed. The galvanizing cause so many pops and holes it was a joke to look at. I wish I had a pic.

Here is my pump fully assembled with the pick up cut to length. I like that the return flows straight toward the pick up. This alone with the pan should keep it from starving with low fuel in the tank. The slope of the tank also feeds to the pan.

Here she is all buttoned up. Can you tell I havent brazed since high school welding? But I feel it is sealed totally now.

So for a total of about $400 I have a new EFI tank for a late second gen. It can support over 500 HP without trouble. I can add another pump or upgrade to a larger pump or pair two together in the sending unit. If I went back to a carb simply pulling the pump out and changing it is easy with the screws. Which all have orings BTW.

For those who may wonder about the quality of the cheapest tank I could find. This is the two cutouts I had. The vent on the stock tank had a dish over it to keep fuel from sloshing into it. The new on is a brazed tube. For $100 I was cool with it.

Here's the new gauges all in the new bezel. The A/F gauge came with a bunch of faces but not one that matched the other ones. If I had a turbo there is a boost face in white. But with just vacuum I'm screwed. Its cool there are some turbos on ebay I have been eyeing. How's that for justification? New turbos so I can use my boost gauge, lol. Maybe we'll see.

I got this pick up with a Walbro 255 for $235. They have a 400 lph pump for $295.

Then grabbed this nice littler recessed pocket that is laser cut to fit the pump.

I got the roll over vent because its cheap and i needed one. Why not get one that fits the left over hole in the pickup?

I took the sending unit out of my stock tank a year ago and let the fumes vent as the may. The tank was mostly empty so I dumped it and filled it will a degreaser and water. Then I said a small prayer and began to cut.

Gravy

After this I dumped the water and wiped out real good. Here is where my problems started. I had bent up some sheet metal that was like expaned steel but with .080" holes. Nice for a baffle I thought. During welding I left my helmet in the car so I tried to weld by brale. No luck! Using the gun to hide the light caused me to burn right through the tank. Dumb SOB! I hate myself sometimes. I was reminiscing during the hole cutting. There a small dent in the tank from the day I got the car 15+ years ago and I was thinking I wouldnt fix it and leave it as a reminder of the day I got my car and towed it over a cylinder block. But it wasnt to be. So I got a new one from Rock Auto for about $100 shipped to my door in three days. Good times!

Where was I? Oh yeah! Making holes! This time I went straight for the plasma cutter and had it over in seconds. I cant beleive I forgot to snap pics of the welds but it was bad. It was brutal. I got lazt and didnt dress the inside of the tank. I wish I had. The galvanizing on the inside of tha tank screwed my welds up so bad I am embarrassed of them. I luckily had two sticks of brazing rod and went over the MIG welds with braze to make sure it was sealed. The galvanizing cause so many pops and holes it was a joke to look at. I wish I had a pic.

Here is my pump fully assembled with the pick up cut to length. I like that the return flows straight toward the pick up. This alone with the pan should keep it from starving with low fuel in the tank. The slope of the tank also feeds to the pan.

Here she is all buttoned up. Can you tell I havent brazed since high school welding? But I feel it is sealed totally now.

So for a total of about $400 I have a new EFI tank for a late second gen. It can support over 500 HP without trouble. I can add another pump or upgrade to a larger pump or pair two together in the sending unit. If I went back to a carb simply pulling the pump out and changing it is easy with the screws. Which all have orings BTW.

For those who may wonder about the quality of the cheapest tank I could find. This is the two cutouts I had. The vent on the stock tank had a dish over it to keep fuel from sloshing into it. The new on is a brazed tube. For $100 I was cool with it.

Here's the new gauges all in the new bezel. The A/F gauge came with a bunch of faces but not one that matched the other ones. If I had a turbo there is a boost face in white. But with just vacuum I'm screwed. Its cool there are some turbos on ebay I have been eyeing. How's that for justification? New turbos so I can use my boost gauge, lol. Maybe we'll see.

#898

Nice job on the tank, looks good. I know what you mean about the gauge face. If you remember I had gotten the white faces for the factory gauges in mine. I got new temp and oil press gauges and the white faces on those are more of a yellowish white and don't match the new faces I put on the others. Sucks. Your new bezel still looks good though! Progress.

#900

Well I don't really yet. Just a '63 Falcon, and a pile of parts! The shed is full with 454, Super T10, 9" Ford rearend, straight axle, Edelbrock BBC heads, tunnel ram, carbs, etc..... But it will be a gasser once it's done!

But it will be a gasser once it's done!

The gas tank looks great! Scarey to start cutting on a brand new tank, huh? Do you plan on putting any sealer over the brazed area, just for extra insurance? The gauge panel looks great too!

But it will be a gasser once it's done!

But it will be a gasser once it's done!The gas tank looks great! Scarey to start cutting on a brand new tank, huh? Do you plan on putting any sealer over the brazed area, just for extra insurance? The gauge panel looks great too!