Project "Wamaro" Build Thread

#13

Got the block in the pressure washer, 180 degree water for 15 minutes.

Next it goes in the magnaflux machine to look for cracks. There were none!

Then the block is put back into the washer to clean the magnaflux solution off and comes out nice and clean!

Next it goes in the magnaflux machine to look for cracks. There were none!

Then the block is put back into the washer to clean the magnaflux solution off and comes out nice and clean!

#15

Got a bit done tonight.

Cut the caps to the correct clearance in the block, milodon says .003 Max

The overall width of the caps did not fit, so i had to cut them to have a .005 interference fit.

Then the caps all fit!

I only had enough time to drill one of the splayed bolt holes in the block. I will finish them tomorrow and thread them also.

Cut the caps to the correct clearance in the block, milodon says .003 Max

The overall width of the caps did not fit, so i had to cut them to have a .005 interference fit.

Then the caps all fit!

I only had enough time to drill one of the splayed bolt holes in the block. I will finish them tomorrow and thread them also.

#19

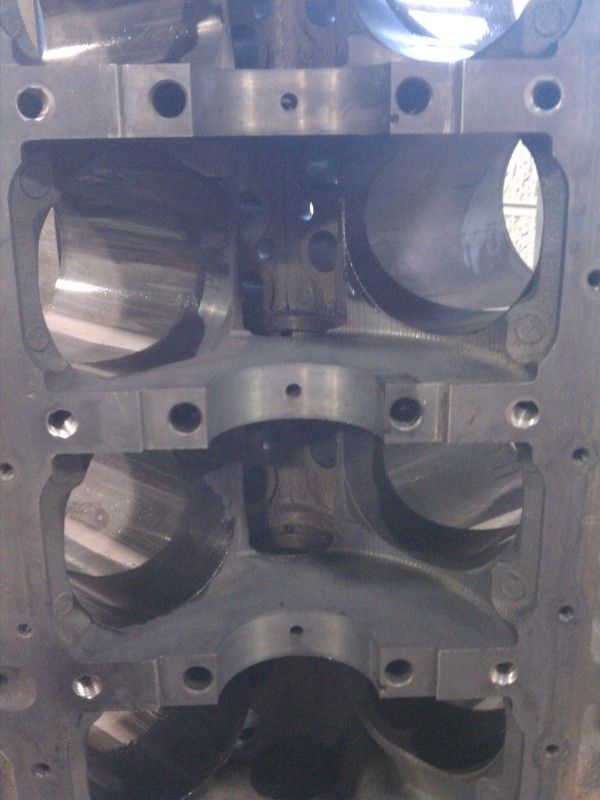

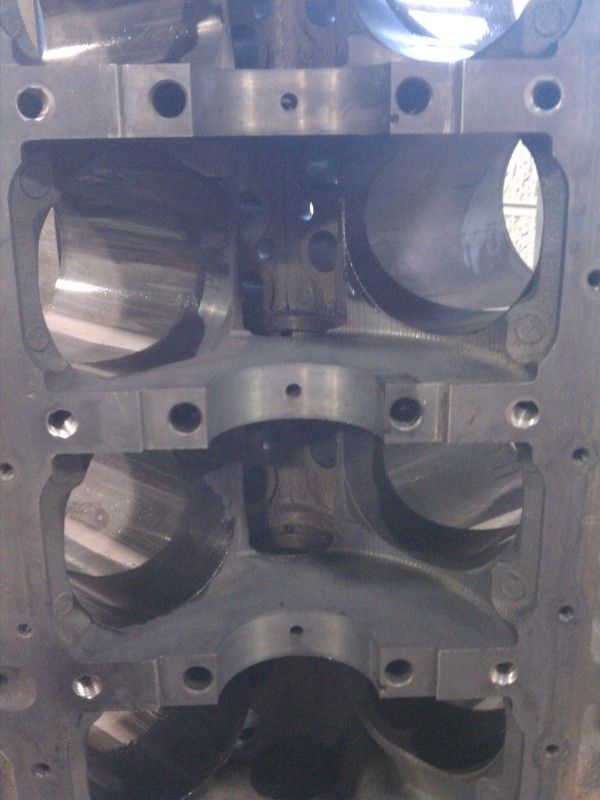

Finished bottom tapping and cleaned in the jet washer

Main studs installed, i have the longer studs for the windage tray, but since i had the short ones form the ARP kit i used them so i can mount the block to the boring machine without problems.

Studs all torqued down for cylinder boring on Wednesday and then line boring/honing next week

Main studs installed, i have the longer studs for the windage tray, but since i had the short ones form the ARP kit i used them so i can mount the block to the boring machine without problems.

Studs all torqued down for cylinder boring on Wednesday and then line boring/honing next week

Last edited by NorthernCrew454; 10-10-2011 at 08:46 PM.